As we work our way through the 2012 harvest season, I’ve had several questions about maturity testing. Maturity testing helps growers plan their harvest scheduling to ensure optimal prices from buyers and, if desired, allow for the longest-term storability.

Here is a quick review of some of the different maturity indices that can be used for apples.

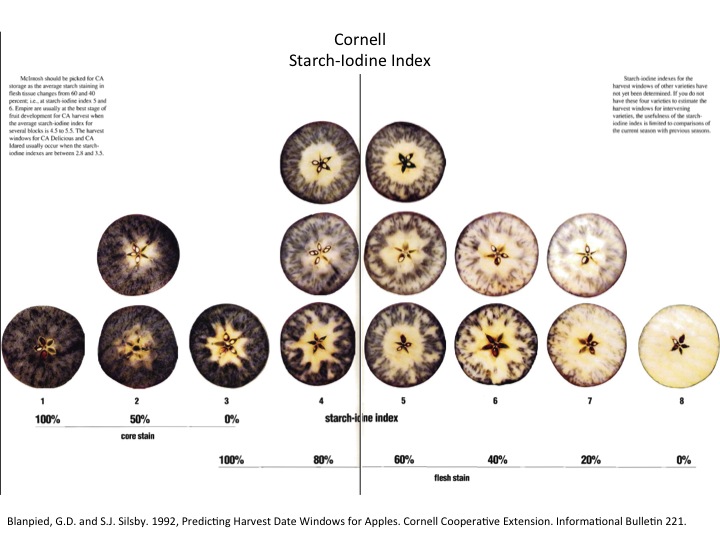

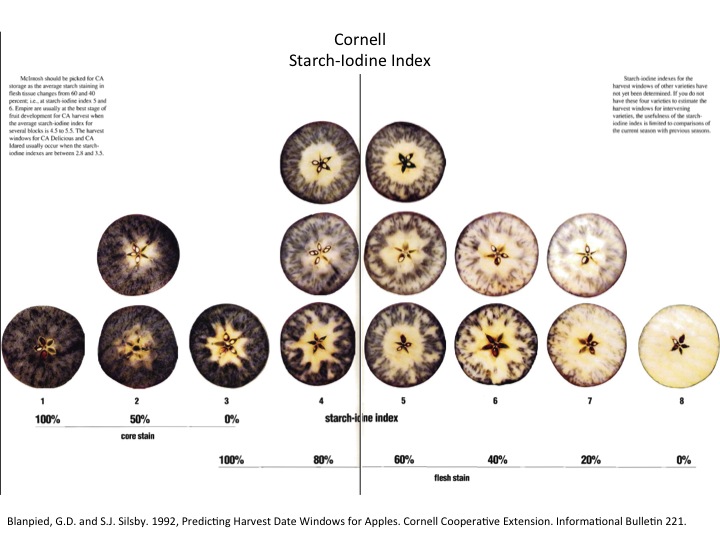

Starch-iodine test: As apples ripen, starch is converted to sugars. In the starch test, iodine binds with starch granules in the fruit and develops into a dark purple to almost black color. The less iodine development (less dark purple color) that you see, the more ripe the apple. Several visual rating scales have been developed to assist with understanding how to rate the various degrees of starch development. A commonly used starch index in the Eastern US was developed by Blanpied and Silsby and can be downloaded for free here: Predicting Harvest Date Windows for Apples. The color chart is located in the centerfold and is often referred to as the Cornell Starch-Iodine Chart (you can also download the below jpg file). Variety specific charts can be found through Google searches on the internet.

Pre-mixed iodine solution can be purchased through Wilson Irrigation in Yakima, WA. However, you can also make your own starch solution following either of the two recipes below:

Recipe 1: Purchase a 2% alcoholic solution of medicinal iodine from your local drug store and mix with an equal amount of water. (Purchasing the iodine at a drug store will be costly if you are going to need a lot of iodine solution during the harvest season.)

Recipe 2: Add 10 grams of potassium iodide and 2.5 grams of iodine crystals to 1 liter of distilled water. The solution may need to sit overnight before the iodine is fully dissolved. The reagents can be purchased through chemical suppliers such as Sigma-Aldrich or Fischer Scientific.

Store the iodine solution in an opaque container, or wrap the container with aluminum foil to prevent direct sunlight exposure. Sunlight will cause the iodine color to fade over time.

Growers and field managers who are visiting numerous orchards throughout the day often fill spray bottles with the iodine solution to conduct tests in the field. A 10-apple sample from a uniform block will usually suffice as long as proper sampling is conducted. Make sure to pick the samples from trees with an average crop load for that block and at a similar location on each tree to reduce within- and between-tree variability. The apples should be cut through the equator since apples do not ripen uniformly from stem- to calyx-end.

Soluble solid content: Soluble solids are measured in the unit •Brix and are a fairly close approximation for the total sugar content. You can find both handheld digital and optical refractometers through several sources, including QA Supply in Norfolk, VA and Wilson Irrigation in Yakima, WA.

Ethylene: In my lab, we use the internal ethylene method where a hypodermic needle is inserted through the calyx into the core cavity of an apple and a 1 cc gas sample is removed. This sample is analyzed by using a gas chromatograph (GC) that has been calibrated with known ethylene standards. As a rule of thumb, when apples are above about 1 ppm they are considered to have started the autocatalytic process known as climacteric ripening. Once apples begin this ripening process, they will increase many of the desirable eating characteristics (increased flavors, aromas, and sugars, and decreased firmness), but they will also begin to decrease in their capacity to maintain quality during long-term storage. Refrigeration, controlled atmosphere storage, AVG (ReTain), and 1-MCP (SmartFresh) will help to minimize additional ripening during storage. However, once the climacteric ripening process begins, it can not be reversed.

Firmness: Apples can be tested for firmness using a penetrometer. You can find handheld and bench-top instruments through several sources, including QA Supply in Norfolk, VA and Wilson Irrigation in Yakima, WA. While not an exact measure of maturity, firmness does decrease during the ripening process and is a very important apple quality parameter.

Size: For processing fruit, fruit size is often used to as a standard for quality. Many processors desire fruit to be a minimum of 2.75 inches, although market demands may influence that size standard. Sizes will also determine the packout and ultimately the value of the apples using USDA grading standards.

Red and background color: Many varieties have market standards for the percent of red surface or background green to yellow color needed to meet USDA grading standards. In general, cool nights will aid the development of color. Poor coloring strains of Red Delicious, Gala, and Fuji apples may need to be left on the tree for longer than their high coloring counterparts.

Flavor: Although we can use sophisticated instruments to quantify the concentration of individual flavor molecules in apples, the best measure is probably the human mouth. Always sample a few bites of your apples before picking to make sure they have the desired varietal characteristics. Picking good tasting fruit is important for all operations, but for those with direct marketing businesses, flavor might be the most important characteristic for determining harvest maturity.

As always, check with your buyer before picking so that you can ensure that you deliver to your customers the apples that will receive highest return.

I will share harvest maturity information for many of the commercially important apple cultivars found in the Winchester area at tonight’s Commercial Fruit Twilight Meeting and on this blog in a few days.

References

Blanpied, G.D. and K.J. Silsby. 1992. Predicting Harvest Date Windows for Apples. A Cornell Cooperative Extension Publication. Info. Bull. 221.

Anon. 1986. Apple Maturity Program Handbook. Washington State Apple Maturity Program. Wenatchee, WA.