Chemical fruit thinning is a critical management practice in commercial apple orchards, aiming to optimize crop production by regulating the number of fruit per tree. This technique involves the application of chemical thinners during the spring to trigger intentional fruit abscission or shedding, known as “thinning.” This blog post delves into the purpose of chemical fruit thinning, its effectiveness, factors influencing its efficacy, and tips for growers to better predict and achieve desired thinning outcomes.

Chemical fruit thinning serves to:

- Increase fruit size: By directing carbohydrates to fewer fruits, thinning promotes the growth of larger fruits, preventing the production of small, undersized fruit.

- Improve fruit quality: Thinning enhances fruit color by increasing light and nutrient availability.

- Prevent biennial bearing: Thinning helps maintain an annual bearing cycle by encouraging the development of sufficient fruiting spurs for the next year.

Various factors influence the effectiveness of thinning sprays, including:

- Chemical selection and rates: Choose chemical thinners based on the fruit growth stage and desired level of thinning, and adhere to label guidelines for proper rates.

- Fruit growth stage and application timing: Apply chemical thinners according to the fruit growth stage, as this can impact efficacy. Most thinning sprays should be completed by 15 mm fruit diameter.

- Use of oils and surfactants: Adding spray oils and surfactants to chemical thinners can improve efficacy but should be used cautiously unless heavy thinning is required.

- Weather: Light and temperature conditions before, during, and after application affect thinning spray efficacy. Low light and high temperatures can increase thinning response.

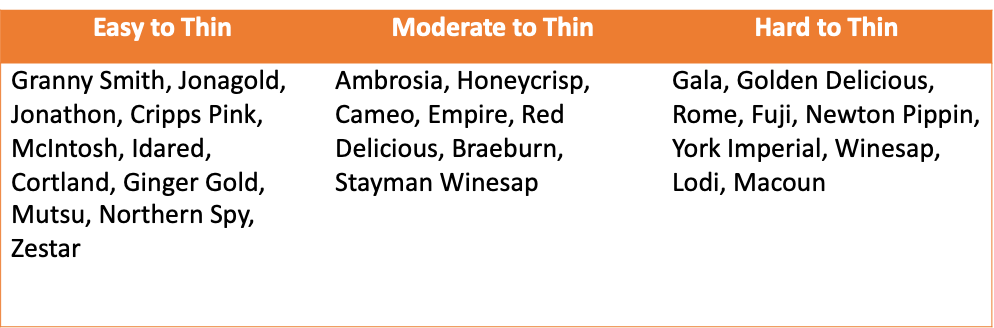

- Fruit variety: Different apple varieties respond differently to chemical thinners. Consult the following table for a categorization of easy, moderate, and hard-to-thin apple varieties.

- Block health and age: Healthy, vigorous, and mature orchard blocks tend to be more challenging to thin than stressed or younger blocks.

- Pruning: Previous dormant pruning can impact thinning spray efficacy, with heavily pruned blocks potentially requiring little to no thinning.

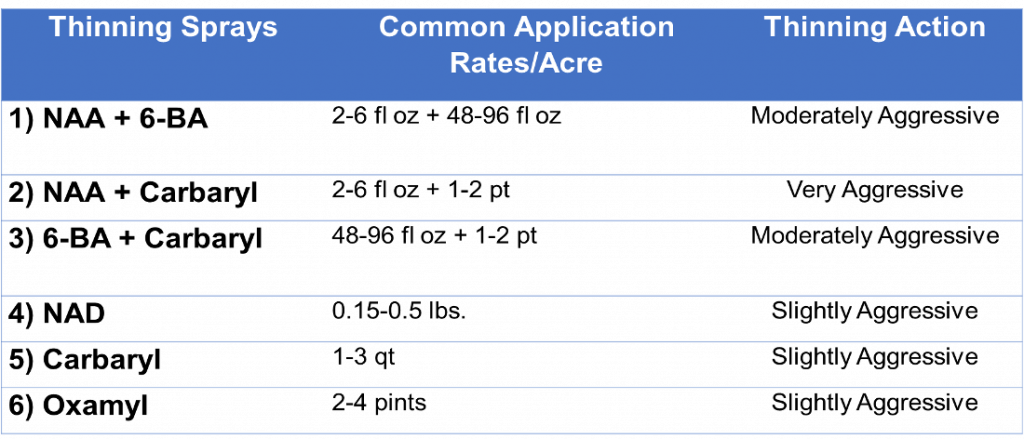

Rates of Chemical Thinners

The rate of chemical thinners is another important aspect that growers need to carefully consider. Most chemical thinners except for carbaryl, oxamyl, and ethephon have rates listed in parts per million (ppm) and fluid ounces (fl. oz.) according to the spray volume. The labels for each chemical thinner commonly supply a conversion chart from ppm to fluid ounces based on the spray volume (gallons per acre). The labels for most chemical thinners typically list a broad range of rates. The level of thinning action is dependent on the rates. When lower rates are used, a lower thinning action can be expected, and when higher rates are used a higher thinning action occurs. When deciding what rates to apply, carefully consider the number of set fruit (crop load), factors which can affect the efficacy (i.e. variety), and always follow the label.

Thinning Spray Applications

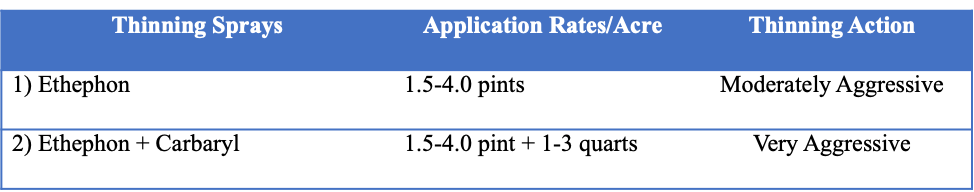

The factors of application timing, chemical thinners, and rates should be carefully considered, evaluated, and selected to develop a thinning spray application which will achieve the desired thinning response. The following tables list several common thinning sprays according to the fruit growth stage, materials, rate ranges, and perceived thinning actions.

Effective thinning sprays (petal fall – 5 mm fruit diameter)

Effective thinning sprays (6 mm – 15 mm fruit diameter)

Effective thinning sprays (16 mm – 25 mm fruit diameter)

Carbohydrate Thinning Model

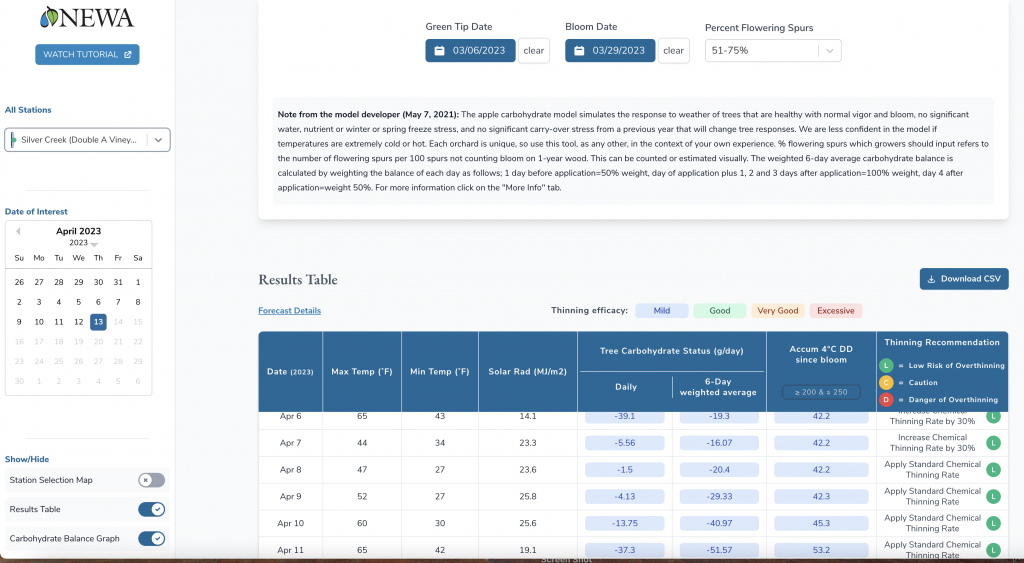

The Cornell Apple Carbohydrate Thinning Model is a valuable tool that assists growers in making informed chemical thinning decisions. Developed by scientists at Cornell University, this model enhances the effectiveness of thinning sprays by calculating the carbohydrate balance in trees, accounting for weather factors such as solar radiation and temperature. Growers can easily access and operate the model through the Network for Environment and Weather Applications (NEWA) webpage, hosted by Cornell University, at the following web address: https://newa.cornell.edu/apple-carbohydrate-thinning.

To utilize the model, begin by selecting the weather station nearest to your orchard blocks. If you prefer to use your own weather station, detailed instructions for uploading your weather station data are available on the NEWA webpage. Once the closest weather station is selected, input your current date, green tip date, and bloom date for the orchard block you want to analyze. The model will then generate a table displaying daily maximum and minimum temperatures, solar radiation, total carbohydrate status, and accumulated degree days since bloom. In the far-right column titled “thinning recommendations,” you will find chemical thinner rate suggestions based on the weather forecast.

Screenshot: Navigating the Cornell Apple Carbohydrate Thinning Model

Disclaimer: The application rates mentioned in this article are based on a concentrate spray volume of 100 gallons per acre and product labels at the time of publication. When applying chemical thinners, use the rates indicated on the labels of the products you are using. The degrees of thinning action are listed according to the author’s personal field experiences. Thinning action may vary from orchard to orchard and block to block.

For additional information on apple fruit thinning, please refer to our extension publication, “Crop Load Management in Commercial Apple Orchards: Chemical Fruit Thinning,” available at https://www.pubs.ext.vt.edu/SPES/SPES-134P/SPES-134P.html.