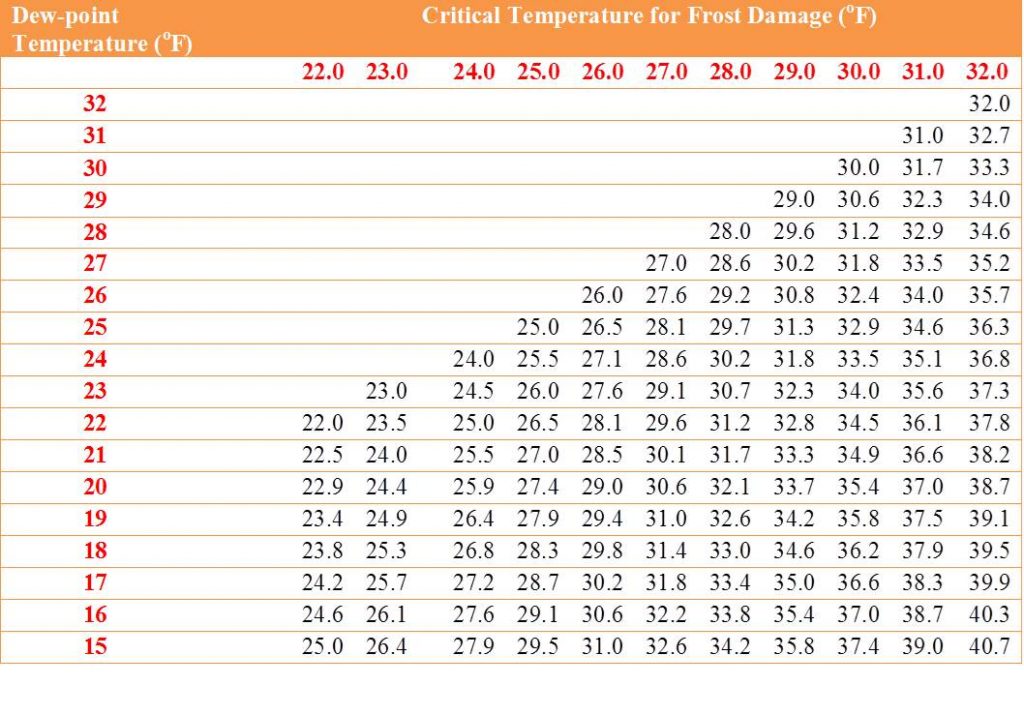

Despite the frost damage we witnessed on March 20 statewide and in some locations on April 8-9, you might be astonished by the quantity of fruits that still need chemical or hand thinning to attain the targeted size and quality. That being said, it is crucial to assess the extent of frost damage in your various blocks and varieties before deciding whether thinning treatments are necessary this season. To learn about the materials used for apple fruit thinning and the stages at which these chemicals are applied, please refer to my previous blog article. The present blog post aims to share the results of the apple carbohydrate thinning model and provide recommendations on timing, rates, and other considerations for orchards in Central Virginia and the Winchester/Frederick County area.

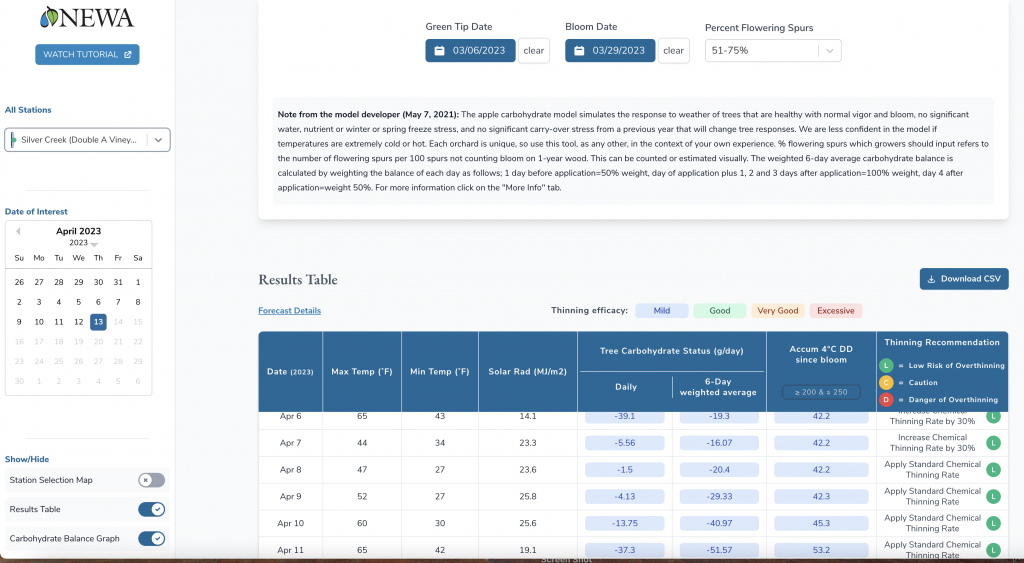

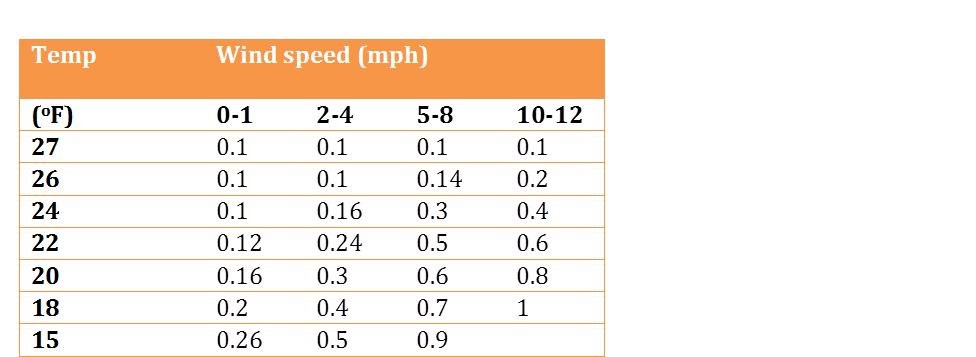

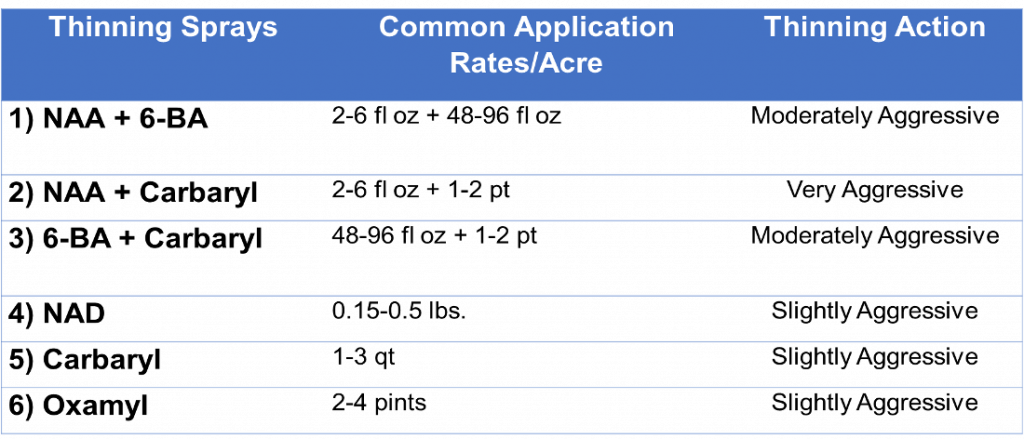

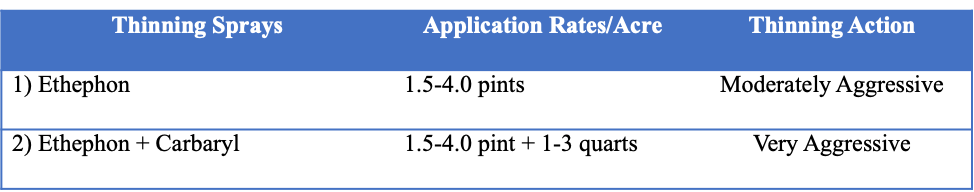

For Central Virginia, I ran the model today (April 16 at 12:00 pm) using the green tip and full bloom dates for Gala as March 6 and March 29, respectively. You should take into account your own dates and varieties when running the model. However, I believe these two dates are suitable for most apple varieties and orchards in Central Virginia. According to this data, we have already reached an accumulated growing degree day (base temperature = 4C) of 209, which falls within the optimal range (200-250) for thinning applications. This range often coincides with a fruit size of 6-15 mm, traditionally considered the most favorable period for fruit thinning. In terms of carbohydrate status, the daily carbohydrate level is predicted to experience a surplus for the next two days (April 17-18), but the 6-day weighted average will reach -15 g/day tomorrow. Trees generally respond more effectively to thinning materials when the 6-day weighted average values range from -10 to -40 g/day. Furthermore, the current forecast indicates temperatures between 65 to 85F this week (Monday to Friday), which is ideal for NAA and 6-BA uptake and effectiveness.

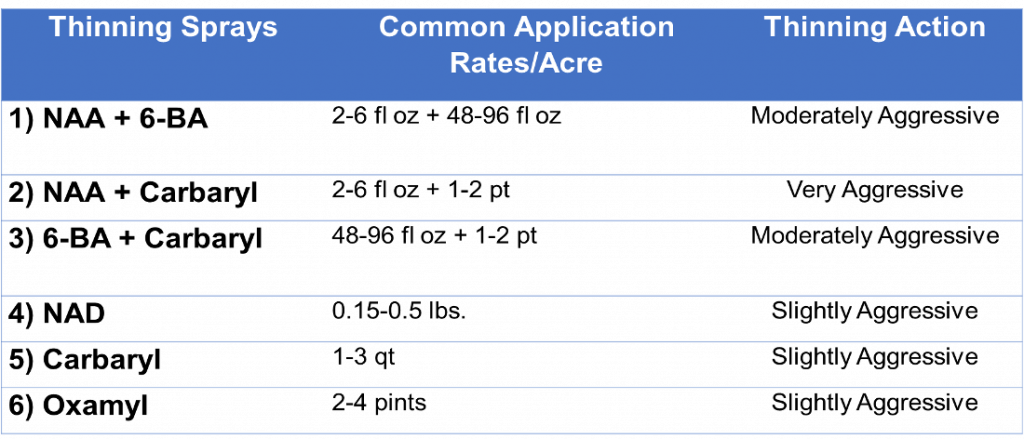

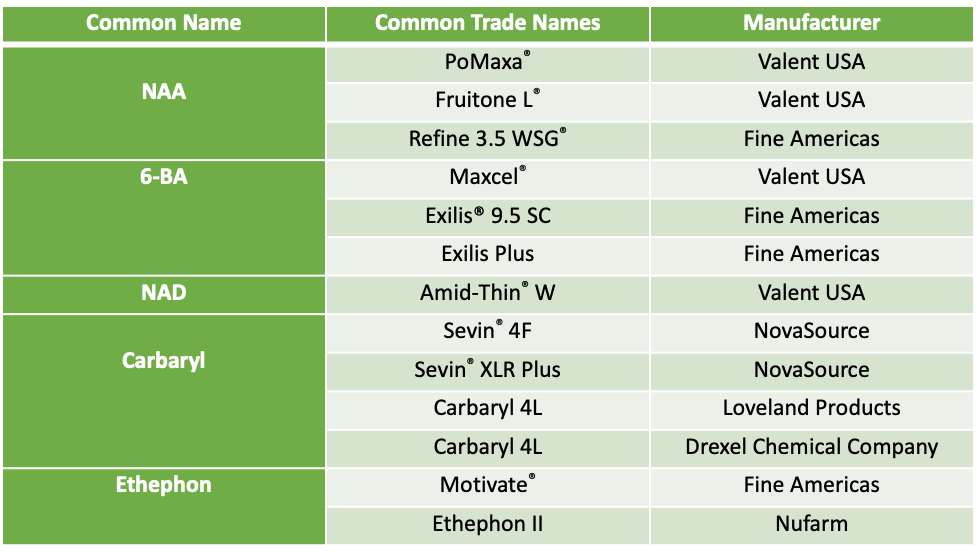

Considering all these factors, I strongly recommend applying your main fruit thinning application within the next four days. If you can complete all thinning applications within two days, opt for Wednesday and Thursday, as temperatures are expected to be around 80F. For tomorrow’s treatment, a standard rate of thinning materials is advised. For example, if you typically apply 64 fl oz of 6-BA (e.g., Maxcel or Exilis plus), 1 qt of Sevin or Carbaryl, and 1 pt of Regulaid per 100 gal/acre as the standard rate, use the same rate tomorrow. For applications on Wednesday and Thursday, more carbohydrate deficiency is expected which may lead to a recommended 15% reduction in your standard rate. However, this cannot be confirmed yet, as it is based on the 6-day average (2 days before thinning and the following four days). Nevertheless, with a projected carbohydrate surplus on Monday and Tuesday and a deficit in the subsequent three days, I believe a standard rate should be used for Wed and Thu applications.

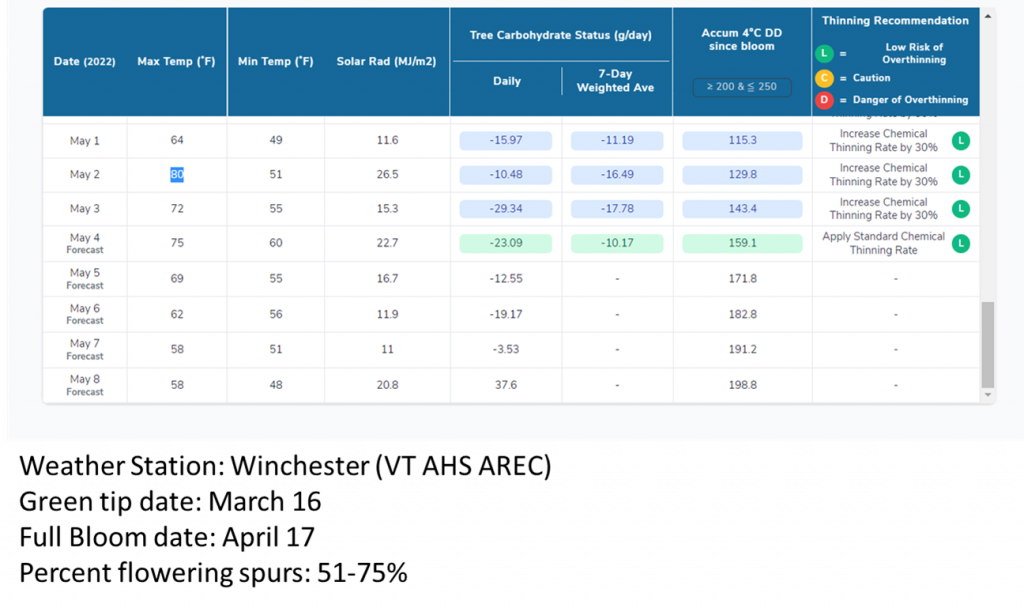

For orchards in the Winchester/Frederick County area, I ran the model for Gala with green tip and bloom dates of March 7 and April 12, respectively. As the model outputs below indicate, the optimal thinning window has not yet arrived. The accumulated DD is below the recommended 200 value, and our average fruit size is still under 5 mm. Therefore, I anticipate that our main thinning window will be around Monday-Tuesday next week (April 24-25), but I will keep you updated if conditions change.