For the past two Octobers, the Jones family has hosted a weekend series of fall activities at their Dinwiddie County farm. However, the rest of the year, they are busy running their full-time dairy operation, which we covered in a previous story. We also wrote about their very first pumpkin patch in 2014.

As they enter their third annual on-farm Fall Festival, the Jones family is offering an array of family-friendly weekend activities including a pumpkin patch, a corn maze, a play zone with activities for children, farm tours, hay rides, a petting zoo, and concessions. The farm will host tour groups on weekdays throughout the month, and on selected evenings after dark, visitors can brave the farm’s haunted corn maze. Visitors can also spot Hermione, Ron, and Harry—a set of triplet Holsteins that achieved viral fame when they were born on the farm last fall.

In anticipation of the farm’s October 8th Fall Festival opening day, I met with Coley Drinkwater, TR Jones, and Brittany Jones on a busy Tuesday afternoon in between farm chores to find out what the family has learned, what has changed, and what is in store for agritourism this October at Richlands Dairy Farm.

Laura: So, you’ve been growing pumpkins for three years—what does it take to get a pumpkin patch ready between spring and October?

TR: Well, the first thing we’re trying to do is decide the size we want them to grow, so we’re basing that on the past fall.

Brittany: We purchase treated seeds. We keep moving planting dates back every year later and later, because they are ready so fast—faster than when they say they are supposed to be ready.

TR: In April we’ll start to disc and plow a field, and then two weeks later, we’ll disc it again, then make the mounds. We’re still hand-planting the pumpkins…which is getting worse and worse every year. [Everyone laughs] From the first year to this year, we’re planting about five times as many pumpkins. We jumped to three times as many this year just so we could start spraying them with the sprayer instead of the hand sprayer, because that’s just time consuming.

Brittany: Yeah, that’s terrible.

TR: And then hopefully it rains. We’ve had to water them every year. We didn’t water them a lot this year, since it’s finally started raining again. Then, it’s just getting them cut off the vine when they’re turning orange.

Brittany: Which is a chore. A huge chore, because you have to go in and find them, and then cut them.

TR: Yeah, and the first year, we planted them in June, June the tenth, and they were done so early. First week of September they were done. Last year we waited until July fourth, and this year we waited until July tenth—we planted about a third, and we planted the last two-thirds around the twentieth.

Brittany: We try to make them last longer for the customers so they’re not sitting in the field.

Laura: How much did you all plant this year?

TR: We planted about five acres. It’s by far the most diverse—this year we added white pumpkins, the warty-looking ones.

Brittany: Yes, warted pumpkins, and we added white gourds.

Laura: You’re embarking on your third year of farm activities. What are you offering this year? What have you added or changed?

Brittany: Well, Coley has added a bunch of stuff for the kids’ area.

Coley: Yes, because we’re finding that this is definitely family-centered. People are looking for some place to take their kids, so we’re trying to keep the kids’ area evolving, adding new things or sticking with things….the cottonseed pit is a big hit. We can never do away with the cottonseed pit. [Laughs] But my overall goal, I think, for the kids area is to do a different theme each weekend next year, so do a soil and water theme, get the soil tunnel in, maybe some vermiculture…really focus on soil. Maybe one we could do is what we grow in Virginia….One weekend, maybe do what we raise, so really focusing on the animals in Virginia, and then maybe do a weekend where we have a popup farmers market, so we’d feature Dinwiddie County, or Dinwiddie-Nottoway, and things that you can actually buy, and meet farmers—that would be pretty cool. I think I’m seeing the fall festival as more of a look at agriculture as whole, with a look at the dairy, but maybe start focusing on dairy more with spring tours in May and June, and really start to promote those. And June is our June Dairy Month Family and Farm Day, and really we really focus on dairy.

TR: I guess the question too is “What did you do different from this year?” so what are you all doing this year that is different?

Brittany: Well, we have the round bales, the fish game…

Coley: We have tic-tac-toe and the tires.

TR: And I imagine that stuff will stay consistent from year to year.

Coley: I will give a shout out to Farm Credit—this year they gave us three iPads to download the My American Farm games for kids to come in and play—it’s basically SOL learning-based games, so I’ve got a tent set up for kids to come in and do that. And then Brittany added the picture board this year and the “How tall this fall?” painting.

Brittany: We added a friendly red-and-white, and we added ducks and turkeys and some poults that I think we’re going to get this afternoon for the petting farm this year.

Laura: Are you doing many tours this year?

Coley: We are booked. This is the first year, starting this coming Monday through October, that we are booked, so we’ve grown a lot with our farm tours since the first year.

Laura: What types of groups come out for those?

Coley: Pre-K, kindergarten, church groups, and then homeschool, is mostly what we get.

Laura: Do you all have any commentary on what it’s like to run a full-time dairy and do this on the side?

[Everyone laughs]

TR: I haven’t made it home before 8:30 this week.

Brittany: It’s perpetually exhausting.

TR: From my side, it’s been backed up because it was so dry I couldn’t get in the field to do anything, and then it got so wet I couldn’t get in the field to do anything, so now I can finally get in the field, but I’m also supposed to be getting ready entirely for this, so now I just have too many things all at once.

Coley: It’s a lot of work.

TR: The weather didn’t cooperate. If the weather kinda spaced itself out, I’d be in pretty good shape. Now I’m sitting here doing audio commentary. [Laughs]

Brittany: Also this month, none of us get a single day off for the whole month, at all.

TR: Even on your weekend off. But I enjoy it on my weekend off. It’s basically like getting to go to a pumpkin patch on your weekend off. On your weekend to work, it’s rough, but on your weekend off, it’s not that bad.

Coley: But I think we’re all good about—even if it’s your weekend off, I’m going to go help Brittany do calves when we’re done, you know, because it’s a lot of work. I think this also creates a unique opportunity for people who come on the tours—like, we’re not done setting up today, and when the tour group got here, I told them that. I was very honest with them that the rain last week just really messed us up, we’re not done setting up, and we are also a working farm, so we have got to get the work done on the dairy farm. That’s got to get done first, then we work on pumpkin patch and corn maze stuff. I think that’s important for people to realize.

TR: For what’s going to open this Saturday, we started setting up not this past Monday, but the Monday before.

Coley: But then, lining up tours, I’ve been working on that since mid-August, kids’ zone stuff since mid-August—we may not be able to physically set it up because of the rain, but there was stuff in the works.

TR: Planning starts, gosh, all the way back in June—what we’re going to have, what we’re going to add…

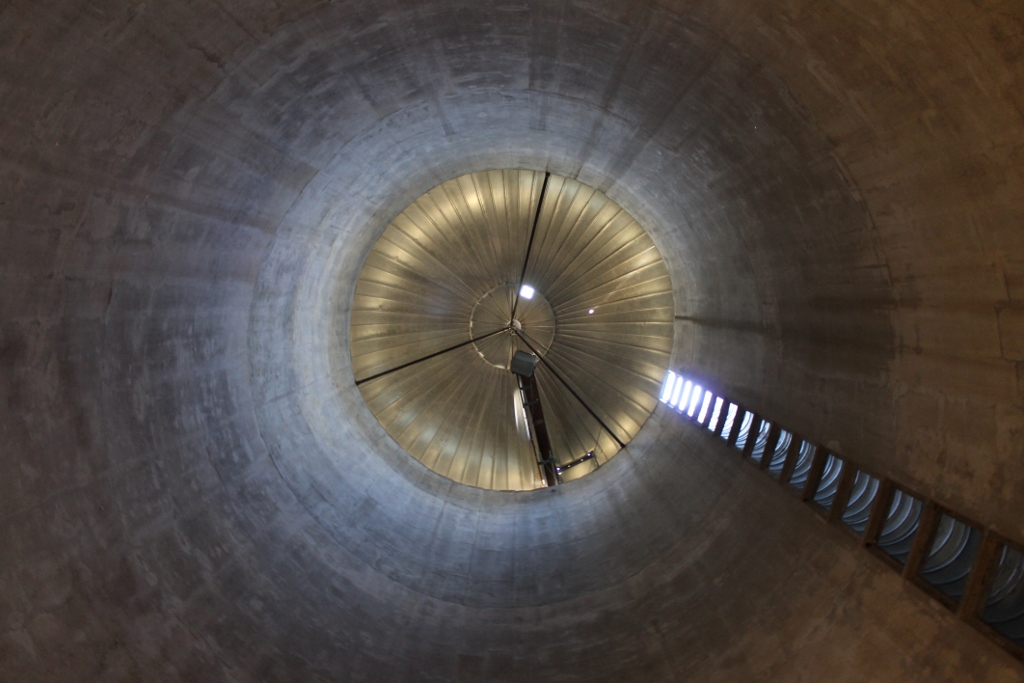

Maze image courtesy of Richlands Dairy Farm

Laura: So tell me, what does it take to create a corn maze?

TR: People are very surprised that we still cut it with a lawnmower. You see so many articles now about how the precision planters will just—you know, you put it in, then you go and plant, and when it comes up, you have a corn maze.

Brittany: That is not how we do it. [Laughs]

TR: We actually have a 30” row planter, so we plant the field once, then we go back and plant it again so we get 15” rows, and then we just sit down and talk about design, and we basically turn it into a grid.

Brittany: And then TR takes his poly posts and marks his grid.

TR: I get some reference points, you know—so this year is an ice cream cone and says “Richlands Creamery 2017,” so basically, I did the bottom of the cone, the top of the ice cream, the top left of the letter R, the bottom right of the Y, and so then I know I have to have “Richlands” spelled by this point, I have to have “Creamery” spelled by this point, and I know how tall it is, then it’s just looking at the thing and saying “This cube equals 10 feet, so I need to take ten steps to get to this next point.”

Brittany: And then Hugh cuts it with the lawnmower behind you.

TR: And then Hugh follows me with the lawnmower, and then afterwards I’m like “God, I hope this is right,” and we get someone to come take a pictures, and so far every year, we’ve been like, “Oh, it’s not bad!” Letters are easy.

Coley: You count down and over.

TR: Yeah, it’s idiot blocks. But the ice cream cone, with swirls and stuff, that’s a little more. The first year, we did the cow faces, and that was—

Brittany: Rough. [Laughs]

TR: That’s a whole lot of just squiggling around. When we got done, they took a picture, and I thought “The first two look exactly right, the third one’s kinda….ehhhh, the fourth one isn’t bad, it has weird ears.” The other thing is there are no do-overs because you’re mowing the corn. And so we did a milk bottle last year and it was supposed to say “Milk the Good Life.” “The” was three letters so it fit easily, and when we did the “good,” we realized we’d scaled it a little bit wrong, and so we had the GOOD life—it was smashed in there! [Laughs] But you don’t get a chance to do it again, it’s a one-time thing

Laura: What’s been your biggest challenge with all of this?

Coley: Balancing the two—just the time commitment.

Brittany: Finding that sweet balance where you’re not neglecting anything on the farm but you’re also not neglecting anything on the pumpkin patch because they’re both our businesses and both need to be treated accordingly.

Coley: I would agree.

Laura: What’s been your greatest success or the thing that makes you the most proud?

Coley: For me, it’s the tours, where you’re actually sharing the dairy and what you do with people. So many people don’t realize what goes on at a dairy farm, so for me, that’s very satisfying, when people walk away with, “Oh that was really cool, I learned so much,”…So just being able to share that in general.

Brittany: Mine is the complete opposite. Mine is when we’re all said and done, we get to buy something we wouldn’t normally be able to buy. So I think this year we are buying a pasteurizer, right?

Coley: [Laughs] Okay, yes. Are we getting cow brushes?

Brittany: Yeah, a cow brush is essentially a luxury item, but because we did so well with the pumpkin patch last year, we can buy a cow brush, and this year, there’s been talk of getting a pasteurizer, and it’s things that make the farm every day easier and better.

Laura: That’s a cool side to consider because people don’t think of it like a business. They just think “Oh, they just do this pumpkin patch.”

TR: And it rolls back into the business. The thing that’s most challenging to me once this gets going—because it’s also harvest time—is getting home super late and not getting to see Hazel [Brittany and TR’s daughter] very much. Like the last ten days, I just haven’t seen her very much. And I like that—you know, I like that two hours of playtime before she goes to bed. So that’s the challenge for me, getting through the day without being able to spend much time with family. But the thing I like, the biggest reward for me when it’s all set up, is that Hazel gets to go to the pumpkin patch every day for a month.

Coley: Yeah, she has the best playground in her front yard right now. [Laughs]

TR: We don’t get to go anywhere on the weekend, we don’t have time off, but we’re all also spending time together, and at the end of the day we’re tired, but we’re usually smiling about it.

Coley: I will say on a day to day basis, that’s my favorite. On that kill time between the pumpkin patch and corn maze and the haunted maze where we’re kind of cleaning up, finishing the barn stuff, getting ready for the next day, we kind of seem to congregate at concession or the kids’ area and there’s a few moments of “Ahhh.”

TR: And we share what was cool about it, you know, “Hey, did you all see the kid who was just over the top about whatever—the cows or the petting zoo?” Or you know, “We had a person on the tour who asked this question, which was a really great question.” Some people ask questions that you don’t think about and you have to answer for, and then for the next tour you have to roll them into your presentation because you think “People should know that!”

Creamery announcement and farm information: Richlands Dairy Farm is excited to announce that they are looking to add a creamery to pasteurize their own milk and to direct-market fluid milk and ice cream locally beginning in late 2017 into spring of 2018. Coley notes that the biggest challenge associated with the creamery is finding a location to build it. The family is working to raise 250,000 of the 1.5 million required to build the creamery. For details about the upcoming creamery, the fall activity schedule, and farm updates, go to http://www.richlandsdairyfarm.com/ , https://www.gofundme.com/298acbdk , or https://www.facebook.com/richlands.dairyfarm/

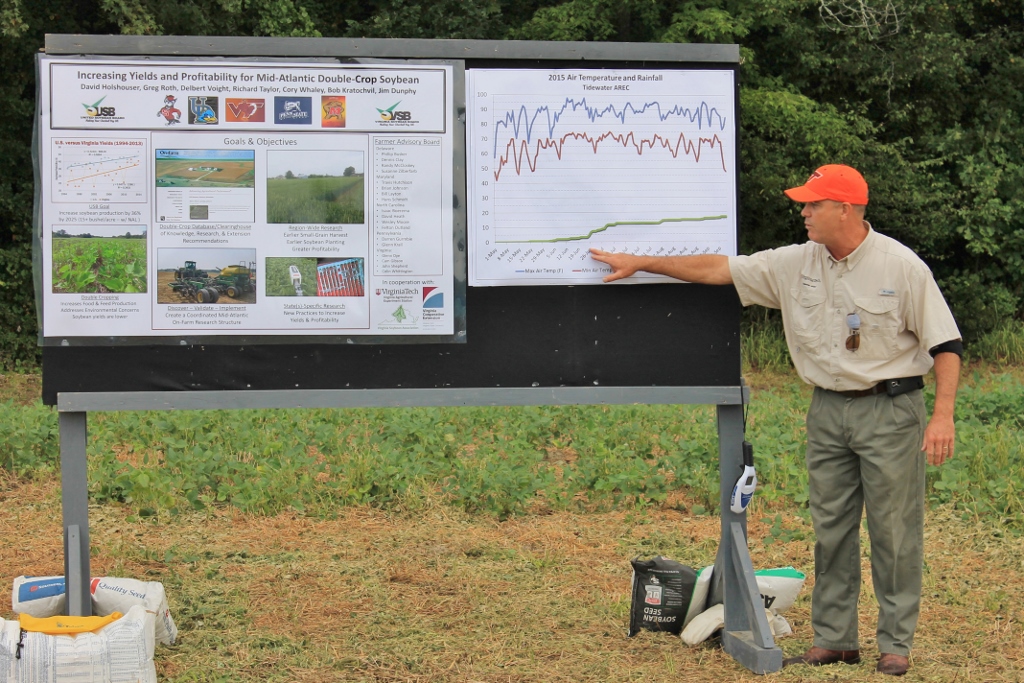

I also caught up with Mike Parrish, Agriculture and Natural Resources Extension Agent in Dinwiddie County, to discuss trends in agritourism in the area and the public value of operations like Richlands.

Laura: Why is agritourism important in this area? Are you seeing growth or changes in interest here?

Mike: It’s just getting off the ground here. It’s important because we’ve got a high urban area around here, so we see the potential to attract that urban population into Dinwiddie to take advantage of some agritourism opportunities….We have people moving into the community, because we are a bedroom community for Richmond and the surrounding area, and so we have people coming in with ideas—they bought a piece of property, and they ask “What can we do with it?”, and they’re looking to be profitable, so agritourism is easier for some of the part-time people to get involved with….As far as new trends go, the biggest thing is that we’ve got some artisans making things like soaps, getting their feet wet in the farmer’s market, and looking at expanding from the farmer’s markets. So the farmer’s markets have the advantage of teaching them a lot—helping them learn how to get in the business and how to market their product, and then they’ll expand. We’ve got a couple that are ready to expand and they’re looking to the county to help…I think some of the proposals by the board of supervisors in the past have made conditions more friendly for agricultural development and business development—that has helped. So Dinwiddie’s really a good cooperator—their administration is really positive about agritourism.

Laura: So in this area, we’ve got operations like Richlands Dairy Farm doing pumpkin patches, farm tours, things of that nature. What benefits do you see for the farms engaging in those types of agritourism efforts, and what are the benefits for people who visit?

Mike: I look at it two-fold. One, it’s profitable for the operation, like Richlands—they’re such a good tight-knit family, and they show how families run farms, and they show a positive image of agriculture and the benefits of having it. And those doing this….they have a good reputation, and they share a good image for the agriculture community, which I see as very positive, and then they’re teaching at the same time, believe it or not. They’re telling what they’re doing. People take some of those practices back to their home gardens—it’s harder for them to replicate it, but I think it spawns interest in agriculture, especially the places that draw the kids out. The kids get to see that kind of career, so I think agritourism does a lot more than just bring money to the county. It helps share the positive image of agriculture.

Laura: How does Extension factor into this equation locally?

Mike: We get a lot of calls in the office each year, so it’s good that we’ve got resources in Extension that we can go to. Of course due to all our other responsibilities I can’t focus on agritourism by myself as a sole job, and you can’t either, but it’s nice that we’ve got people like Martha Walker [Extension Specialist—Community Viability], and Martha’s got her connections, so we have these go-to people and we have other agents around who have even more agritourism in their communities that we can call and talk to……so I think Extension—our network of resources—is a benefit to producers, and if they see the big farmers working with us, then the little ones want to work with us too and see the benefits. We’re all going for that same goal of staying profitable and using the land for ag. Within Dinwiddie, we’ve had meetings jointly—we’ve held a couple agritourism programs with the county and tried to encourage it, and we advertise all the neighboring start-up business programs, like efforts with Virginia State University, so we try to be a partner as much as possible.

Laura: Any parting advice for people who might be considering an endeavor in agritourism?

Mike: Niche agriculture and agritourism still face the same challenges that row crop production does. It’s not going to be peachy every year, so they need to build in the type of management structure that can handle environmental issues with the weather, or seasonal changes. It’s not like having a business that can be open 24/7 or run 9-5 all the time, so I think that’s an eye-opener for some of the people that get into it. It’s farming. It might be just a pumpkin patch to you, but to get to a pumpkin patch, it’s farming. It’s not just a business that pops up all of the sudden, and that’s what I think a lot of people who come out to agritourism operations don’t understand—how much work it took to get to that point. It’s actual farming. It might not be huge farming, but it’s farming.

Additional Resources for Readers:

SOVA Agricultural Experience (agritourism directory)

Virginia Cooperative Extension Agritourism Resources

My American Farm app and games